We designed a stackable furniture collection to lower the rotational molding furniture supply chain carbon footprint: the Stacky collection

Rotational-molded furniture generally requires a lot of shipping-space. How can we improve that?

Improving the rotational molding carbon footprint

The design inputs came from connecting the dots between two past experiences. The first came while designing the Fortezza doghouse for the Pet Collection. We learned rotational-molding products require a lot of shipping space due to their often big size.

The second input came while designing mass-market furniture. We learned about the efficient shipping-space benefits: a lower supply chain carbon footprint and lower shipping costs.

So, with insights about these two experiences, we asked ourselves: how can we improve rotational-molded furniture shipping space? How can we design a lower carbon footprint rotational molding furniture collection?

Plart is a brand with great rotational molding expertise, manufacturing also for the best Italian furniture brands. So, we asked them: is the rotational-molding furniture size a real shipping pain point?

Testing the need

We involved Plart because we need to test if the need was real. Thanks to the first calls with Samer, the Plart Marketing manager, we understood that rotational-molding furniture size was a shipping pain point.

What’s more, requiring a lot of shipping-space, means higher costs. Thus we got two needs: a sustainability one and an economical one. There were enough pieces of information to design an improvement, to sit again at the drawing board.

Then, we asked ourselves: what if we keep just functional surfaces to make the products stackable?

Keeping just functional surfaces

Rotational molding technology is well-suited for outdoor furniture. In the market, the most popular products were tables, armchairs, and sofas. So we focused on the latter.

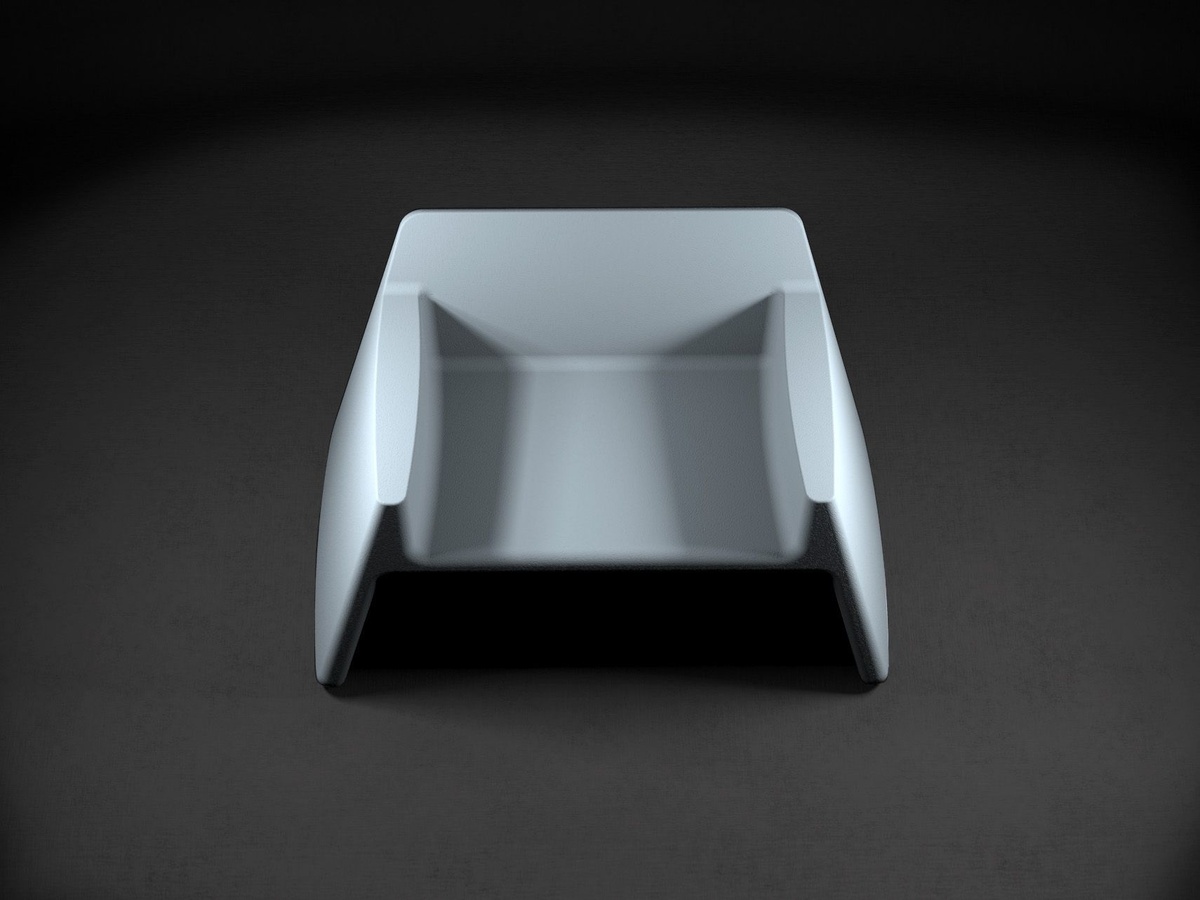

These products are often designed as a large volume, even if it is not strictly needed: the sofa and armchair functional surface is the sitting one, while the coffee table one is the top surface.

So we got an intuition: what if we keep just functional surfaces and make the products stackable? Having stackable products means optimizing shipping space, lowering the supply-chain carbon footprint.

Making stackable rotational-molding furniture for a low carbon footprint supply chain work.

Developing the product together

The vision of the concept was good. But feedback from the manufacturing was still missing. With rotational molding, larger straight surfaces can slightly wobble if touched, and this is a synonym for poor quality. Not the desired outcome.

Luckily we got the precious company technicians’ feedback. Their tip was to design slightly rounded surfaces. This way, the plastic shell acquires much more stability, obtaining higher perceived quality.

Low carbon-footprint rotational molding furniture

In the end, together with Plart, we designed a stackable rotational molding furniture collection optimizing shipping space. Keeping the functional surfaces and taking apart all the rest allowed us to put more products in a single shipping truck for a low carbon footprint supply chain.